4065 N. Woodlawn #4 || Wichita KS || 67220 || (316) 681-3566

Induction Heat Stations

(Stationary and Handheld)

Applications:

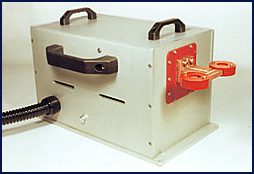

Heat Station features a 4-position tap switch to easily vary coil voltage when different sized or shaped coils are required. |

Shown with dual heating coils for heating of 2 parts at one time. |

Features:

|

|

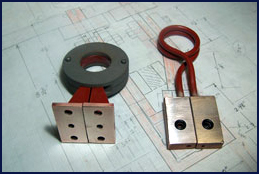

A Quick Change Adapter is available. It allows substitution of different heating coils without tools. A simple 1/2 turn of the top knob releases the heating coil. |

The Standard Heating Coil (left) mounts with 4 screws to a mating flange. Quick Change Heating Coil (right) is the type used with the Quick Change Adapter. Both Heating Coils have silver plated contact surfaces. |

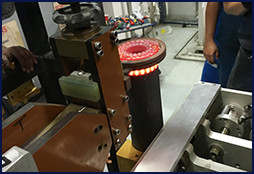

Heating 3" diameter threaded nut for oil refinery vessel repair. Thumb switch controls power. Power unit weight: 8 LBS. |

INDUCTION HAND UNIT WITH 10 METER FLEXIBLE CABLE. |